Common raw materials used in sheet metal fabrication

Sheet metal fabrication encompasses the use of various raw materials, each with its own unique characteristics and advantages. Aluminum, known for its lightweight and corrosion-resistant properties, is a popular choice in industries such as aerospace and automotive. Stainless steel, on the other hand, offers excellent strength and durability, making it ideal for heavy machinery and architectural structures. Copper, with its excellent electrical conductivity, is commonly used in electronic components and wiring.

Selecting the right raw material for a specific project involves considering factors such as strength, weight, corrosion resistance, and cost. By understanding the properties of each material, manufacturers can make informed decisions that ensure the final product meets the desired specifications and performance requirements.

Forming and bending methods in sheet metal fabrication

Forming and bending are key processes in sheet metal fabrication, allowing manufacturers to create complex shapes and structures. Press braking is a commonly used technique that involves using a machine press to bend the metal sheet along a predetermined axis. This can be done using V-dies, U-dies, or other specialized tooling depending on the desired shape.

Roll forming, on the other hand, is a continuous process where the metal sheet is passed through a series of rollers to gradually bend it into the desired shape. This method is often used for producing long, uniform profiles such as rails, tubes, or channels.

Another popular method for forming and shaping sheet metal is hydroforming, which utilizes hydraulic pressure to shape the metal sheet into complex contours. This technique is especially useful for creating intricate and seamless parts with high structural integrity.

Applications and Examples of 3D Printing Uses

Replacement Parts

For replacement parts, 3D printing is useful for consumers because there are no long lead times or running around to pick up parts. 3D printing lets consumers and businesses maximize the value of their purchases and focus on more important things.

Aeronautics and Space Travel

Humans are always working to expand our presence in space. 3D printing allows for the on-demand creation of tools, equipment, and entire structures in space and extraterrestrial environments. Back on Earth, 3D printing can make advanced aerospace components like airframes, avionics housings, and more. Overall, 3D printing can help make space travel more cost-effective and thus help create a more sustainable human presence.

Custom-Fitted Personal Products

Lots of everyday objects are designed for the average body type and size. Chairs, clothes, keyboards, and desks are all made for a person of average build. This makes things hard for anyone outside of that average size, leading to discomfort and even disability. 3D printing gives people the option of custom-fitted personal products for better ergonomics, comfort, and safety.

Educational Materials

3D printing gives students tactile objects that they can use to boost their learning process. Things like topographical maps help students better understand the topics they’re learning about. 3D printing can help boost creativity, improve learning habits, and foster collaboration.

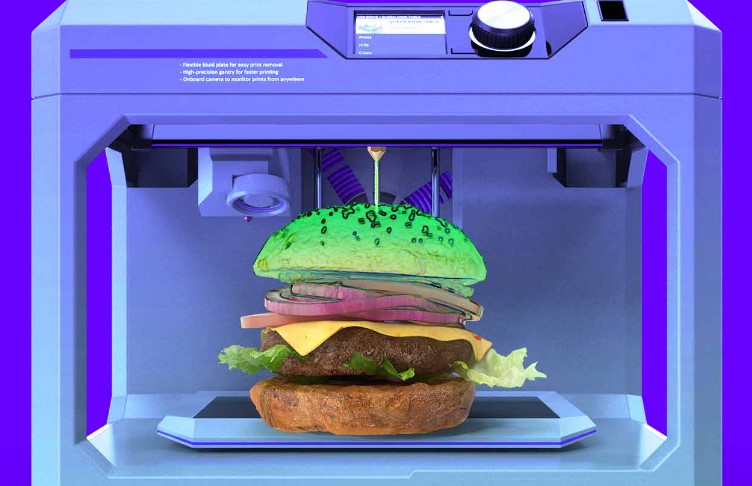

Food

This one is quite hard to believe, but even food can be 3D printed. Labs are already growing meat and vegetables using stem cells. In the future, scientists can use 3D printing to create enough quantities of fruits, vegetables, and meat to feed the growing population and reduce the land used for livestock and agriculture.